Unpacking the Importance of Component Maintenance Manuals (CMMs): 5 Key Factors to Consider When Choosing Your Support Team

The aviation industry provides and supports over 87.7 million jobs worldwide and contributes $6.3 trillion to the global economy. It should come as no surprise that aircraft safety is vital to the continued success of this business. A major factor of safety is the use of reliable, current technical data. Component Maintenance Manuals (CMMs) are one example of the types of technical data used by aircraft maintainers. In this blog post, we’ll explore what CMMs are, why they are important, and five things to consider when choosing a company to support you in the creation of CMMs.

What are Component Maintenance Manuals?

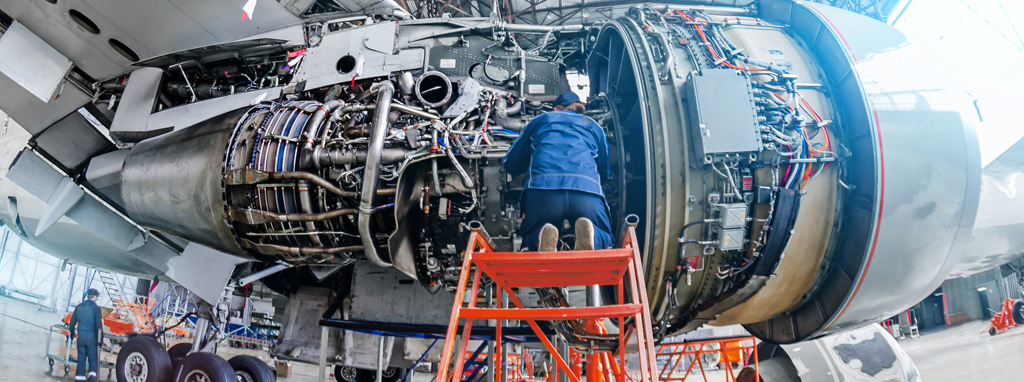

Component Maintenance Manuals are Federal Aviation Administration (FAA)-approved formal technical data documents that provide detailed information on how to accomplish off-aircraft maintenance tasks on aircraft components. They are typically created by the original manufacturer of the component and contain a variety of information, including detailed descriptions of the component, instructions for installation and removal, maintenance procedures, and troubleshooting guides. They are critical documents that ensure the safe and efficient operation of aircraft.

Why are Component Maintenance Manuals Important?

CMMs are important for several reasons.

- CMMs provide maintenance personnel with detailed instructions on how to remove, maintain, repair, overhaul and install components. Ensuring components are maintained properly provides a safe aircraft ready for the operation or mission.

- CMMs are important for regulatory compliance. Aviation authorities such as the FAA and the European Aviation Safety Agency (EASA) require that aircraft components be maintained according to specific standards. CMMs provide the guidance necessary to ensure maintenance is performed in accordance with these standards.

- Third, CMMs are important for liability purposes. If an aircraft component fails and causes an accident, it is essential the maintenance records for that component are available and maintenance is performed in accordance with the manufacturer’s instructions. CMMs provide the documentation necessary to demonstrate the component was maintained properly.

Who Can Provide Me the CMMs Required for Maintenance?

There are five things to consider when choosing the right company to support you in the creation of CMMs. Here are five things to keep in mind:

- Experience and expertise: The company you choose should have experience creating CMMs and should have a team of experts who understand the requirements and regulations for these documents.

- Quality control: CMMs must be accurate and consistent. The company you choose should have a quality control process in place to ensure all CMMs are created to the highest standards.

- Customization: Your company’s components may have unique characteristics that require specific maintenance procedures. The company you choose should be able to customize the CMMs to reflect these requirements.

- Technical writing: CMMs are technical documents that require specific writing skills and standards. The company you choose should have technical writers who are experienced in creating these types of documents.

- Support: Once the CMMs are created, you may require ongoing support from the company. Make sure the company you choose offers ongoing support to ensure your maintenance personnel have access to the latest information and updates.

In conclusion, CMMs are critical to the safe operation of aircraft component maintenance. When choosing a company to support you in the creation of these documents, consider their experience, quality control process, customization capabilities, technical writing expertise, and ongoing support. By taking these factors into account, you can ensure your CMMs are created to the highest standards and your maintenance personnel have access to the information they need to maintain your aircraft components properly.

Fortunately for you, ONEIL has been supporting aerospace customers since 1947, leading the way in technical publications, product support analysis, legacy data conversion, and much more. We are compliance experts with specification requirements including S1000D™, S3000L, ATA, GAMA, and Mil-Spec. We have industry-leading expertise in developing IETMs, AMMs, CMMs, FIMs, Work Cards, TOs, TMs , and more. Simply put, if it supports your product, we create it.

Related Resources: